By Jim Lewis, CEO Enhanced Retail Remedies LLC

I recently experienced the honor of lecturing at my alma mater, the University of Florida. We talked about the basic principles of retail analytics, the applications and roles of retail and wholesale stock planners. We talked about how products selections are built to hopefully make magic on the revenue floor. But the magic doesn’t normally occur.

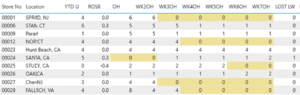

A scholar requested what triggers a retailer to have empty shelves. That’s a total lecture inside alone. We talked about some of the causes- what can be managed and what can’t. They know what they browse- that the pandemic prompted havoc on the supply chain. While that is authentic, there are many other leads to, primarily now that the source chain is easing. We concentrated on learning the mechanics of how out of stocks final result in misplaced product sales. A single of the stories I confirmed the stock of an merchandise by retail outlet by week, highlighting when it was out of stock. Learners quickly did the math to determine out how significantly cash was getting still left on the table.

Keep track of stock by sku by week by keep to discover outs and dropped prospect.

Predicting Out of Shares

When there are some shops whose philosophy is that they’d somewhat be out of stock than mark down an item, the huge greater part don’t want to be out of inventory. Avoiding stock outs demands a large amount of going parts to sync harmoniously. There need to be a steady move of stock coming from the wholesale side with peaks and lulls taken into thing to consider. The allocation method depends pretty considerably on the sophistication of the retailer. Some car replenishment methods only stick to a minimal amount, some increase level of sale to that, but most aren’t smart sufficient to prioritize shops and things that are out the most. And many really don’t increase again shed gross sales, which suggests the total foundation for the forecast does not replicate the genuine opportunity. Then there is the sheer volume of sku’s- thousands and thousands of sku-keep combinations to take care of.

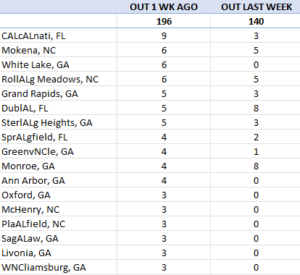

Hold observe of the retailers or objects that are constantly out of stock.

VMI

The ideal approach for staying in inventory is VMI (Vendor Managed Stock) wherever the retailer employ’s their supplier’s resources to forecast and make certain shops continue to be in stock. It mainly indicates those people sku’s will have a lot more emphasis on them than non-vendor managed goods. This target permits the provider laser concentrate on suppliers and sku’s that are most most likely to go out of stock, and beef them up.

Scenarios

Even with the finest of intentions, there may well not be sufficient stock or open to invest in to allocate in the most successful method. Which is why documenting scenarios is critical. If you only have so quite a few methods- which suppliers or items will get fed to start with? What gets prioritized? Or does each and every retail store get a more compact amount? These might modify dependent on the circumstance, but we endorse producing a “play book” so there is a approach in area.

Information Science

It truly isn’t brain science. We have an abundance of studies and systems that constantly review which goods and shops are offered out- so that stock can be prioritized to repair the challenge. Based mostly on a mix of facts factors- wholesale inventory flow, historic retailer and merchandise stock outs, seasonality, promotions, etcetera., we use a few basic algorithms to do the work. It does demand potent computing electrical power to sift by means of tens of millions or billions of records of facts, so it is not for the faint at coronary heart.

I generally love chatting to learners. At its coronary heart, ERS was started on education and learning- teaching producers to feel and act like retailers. It has progressed into significantly a lot more more than the past 20 yrs, but teaching stays a main concentration of our business enterprise.

For a lot more facts, contact us.